HDPE Sheet

HDPE Sheets – Lightweight, Tough, and Long-Lasting

YAKAI HDPE Sheet, also known as PE100, is a versatile and durable material, widely used in tank building, construction, marine, and industrial applications.

Get direct supply factory, Choose your custom sizes

Why Choose Us

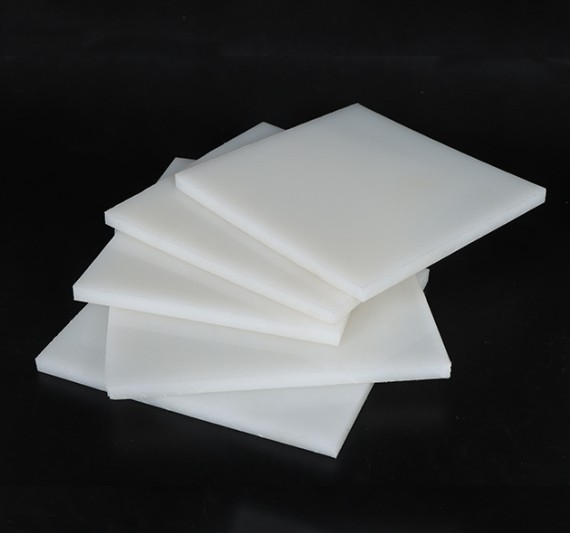

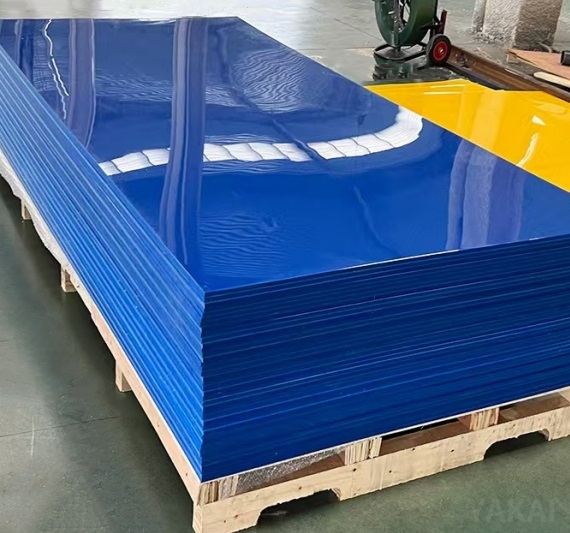

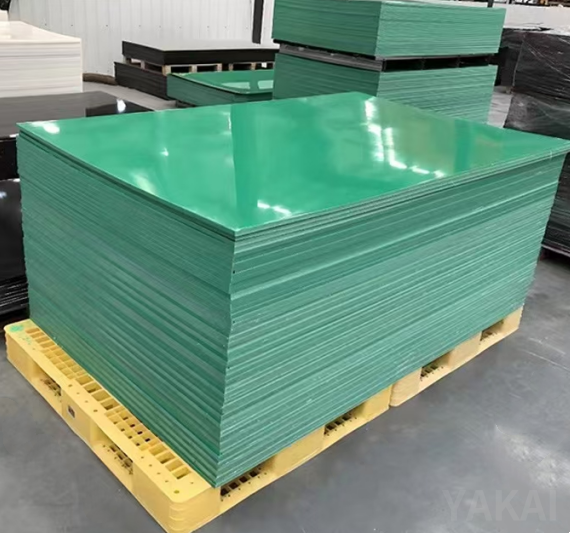

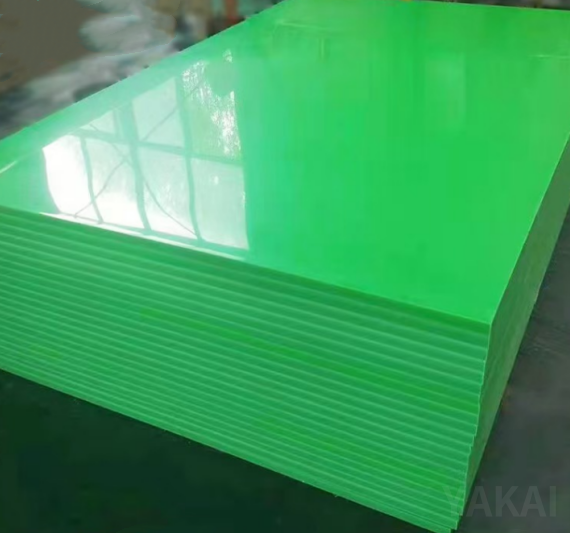

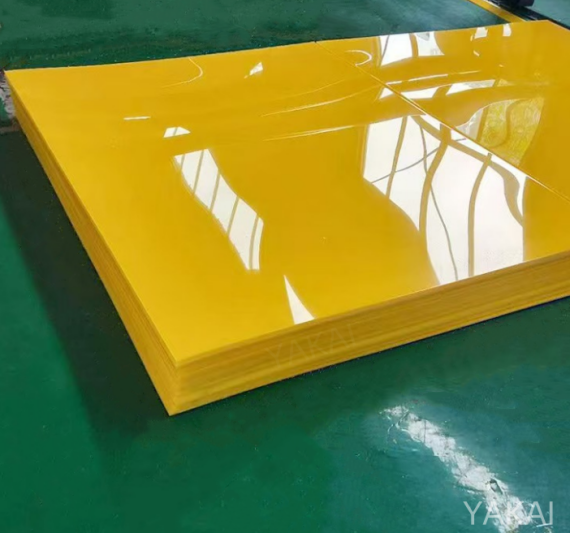

Custom Coloures Available

Custom Size Available

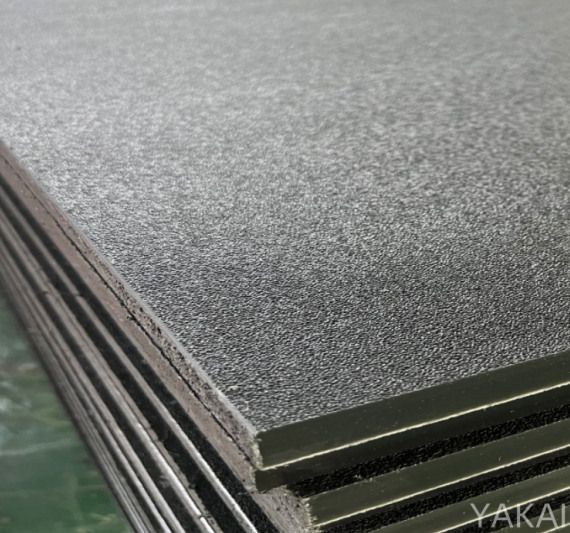

Customizable Surfaces Available

YAKAI HDPE Sheet is your go-to solution:

- Weather and UV Resistance: HDPE sheets can withstand harsh outdoor conditions, including extreme temperatures, moisture, and prolonged UV exposure, without degrading.

- Chemical and Corrosion Resistance: They exhibit high resistance to a variety of solvents, acids, and corrosive substances, ensuring longevity in demanding environments.

- Lightweight and Easy to Fabricate: Despite their strength, HDPE sheets are lightweight and can be easily cut, welded, and shaped, facilitating customization for specific applications.

- Non-Toxic and Food Safe: Many HDPE sheets comply with FDA standards, making them suitable for food processing, packaging, and medical applications.

- Working Temperature Range: Reliably performs in temperatures ranging from -50°C to +80°C.

YAKAI HDPE Sheet Applications

- Industrial: Machine liners, conveyor slides, parts for automation equipment

- Agricultural: Livestock enclosures, water tanks, lining for breeding containers

- Transportation: Truck bed liners, dock bumpers, sliding surfaces

- Construction: Formwork, water barriers, wall protection boards

- Food Processing: Cutting boards, workstation surfaces, food-grade machine components

- Signage & Advertising: Popular for outdoor signs, display boards, and engraving materials.

- Marine: Dock fenders, boat parts, marine piling protection, seawall facings, floating platform surfaces

YAKAI HDPE Sheet – Delivery & Customer Service

Full Fabrication: CNC machining, router cutting, and assembly for complete product solutions.

Worldwide Delivery: We ship to Australia, USA, UK, France, Germany, New Zealand, Singapore, South Korea, Japan, Thailand and more

Flexible Order Quantity: From sample sheets to bulk supply

Customer Cases

Cut-to-Size Service for Australian Client

Textured HDPE Sheets for U.S. Client

HDPE Sheet Fabrication for French Client

What Our Clients Say

The cut-to-size HDPE sheets we received were perfect. The dimensions were accurate, and delivery was fast. Very satisfied!

James, Australia

They are nice because they are as easy to work with as wood. The material is nice and flat. I especially appreciate the different textures on opposing sides since it means I can opt for smooth or textured depending on my need.

Abigail, United States

High-density polyethylene is such a versatile material; easy to machine, food-compatible in most cases, and easily recycled. The sheets are decent, clean, smooth, and dimensionally accurate. No complaints.

Marc, France

FAQ

What are the types of HDPE Sheets?

HDPE sheets can be categorized based on their properties and applications. The main types include:

1. General-Purpose HDPE Sheets

Suitable for a wide range of applications, including industrial, construction, and agricultural use.

Offers excellent chemical resistance, impact strength, and weather resistance.

It can be easily machined, cut, and welded.

2. UV-Stabilized HDPE Sheets

Enhanced with UV stabilizers to prevent aging and fading under prolonged outdoor exposure.

Ideal for outdoor signage, marine components, and open-air storage applications.

3. Food-Grade HDPE Sheets

Complies with FDA standards, ensuring safety for direct food contact.

Commonly used in food processing, cutting boards, and food storage containers.

4. Color-Core or Multi-Layer HDPE Sheets

Features different colored layers, making them suitable for engraving and laser cutting applications.

Widely used for signage, labels, and decorative engraving projects.

5. Conductive & Anti-Static HDPE Sheets

Designed with conductive or anti-static properties to prevent static buildup and protect sensitive electronics.

Commonly used in electronics manufacturing, cleanroom environments, and hazardous material storage.

Each type of HDPE sheet serves specific applications, and choosing the right material ensures better performance and longevity.

Does HDPE Sheet have other names or abbreviations?

Yes, HDPE sheet is known by several other names and abbreviations, depending on the industry or application. Here are some common ones:

1. Full Name & Abbreviation:

HDPE – High-Density Polyethylene

PE300 – Common in the UK and Europe to distinguish it from lower-density polyethylene grades

PE100, PE-HD, High Density PE but these are often just brand-specific names.

PE-HD – Another abbreviation used interchangeably with HDPE

2. Trade or Common Names:

Polyethylene Sheet – General term (can refer to LDPE or HDPE, so it’s less specific)

High-Density Polyethylene Sheet – Full descriptive name

What is the density of HDPE sheets?

HDPE sheets typically have a density of 0.93–0.97 g/cm³, making them lightweight yet strong.

Do HDPE sheets absorb moisture?

Very little. With an absorption rate of less than 0.01%, HDPE remains stable in wet or humid environments.

Are HDPE sheets resistant to chemicals?

Yes. HDPE is highly resistant to most acids, alkalis, and solvents, making it suitable for chemical storage and industrial use.

Can HDPE sheets be used outdoors?

Yes. UV-stabilized HDPE resists sunlight and weathering, making it ideal for outdoor applications.

Is HDPE safe for food contact?

Yes. HDPE is FDA-approved for direct food contact, food- contact grade HDPE widely used in kitchens and food industries.

What are the main applications of HDPE sheets?

Common uses include chopping boards, food processing, chemical tanks, playground equipment, and packaging.

What does “thermoplastic” mean in HDPE?

It means the material can be heated, shaped, and cooled repeatedly, making it easy to process and fabricate.

Are different colors available?

Yes. HDPE sheets can be produced in various colors for safety coding, branding, or design purposes.

Can HDPE be recycled?

Yes. HDPE is a 100% recyclable plastic, commonly reused in pipes, containers, furniture, and construction materials.