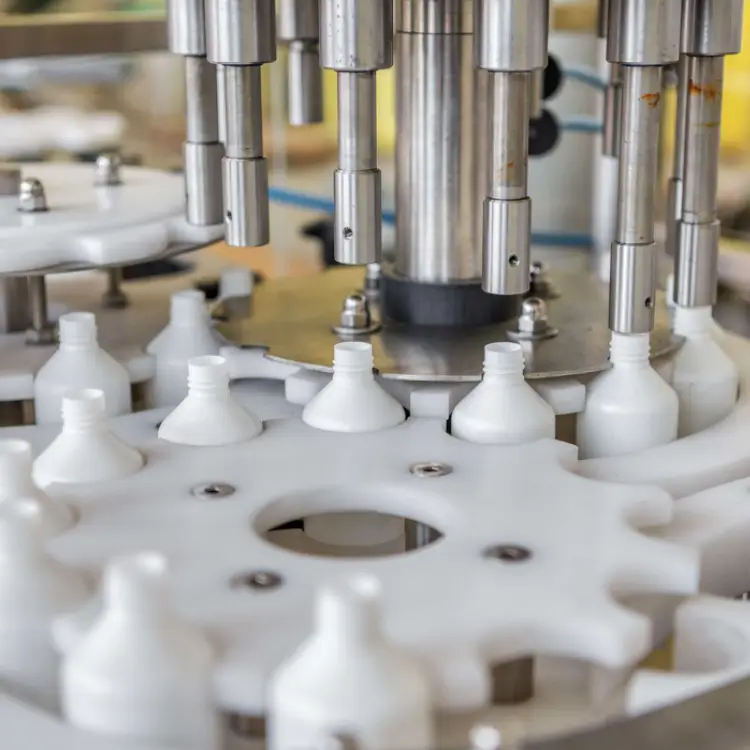

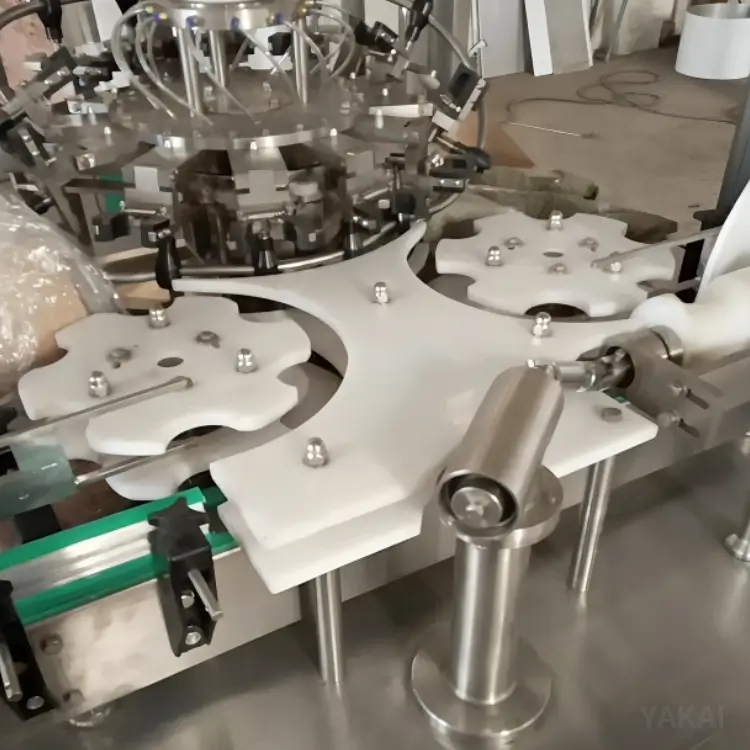

UHMW Sprockets

No rust. No noise. Silent. Self-lubricating.

Engineered for performance and longevity, our UHMW plastic sprockets deliver reliable power transmission with reduced noise, zero rust, and minimal maintenance—ideal for demanding industrial and hygienic environments.

UHMW Sprockets Information

We specialize in manufacturing high-performance sprockets made from Ultra-High Molecular Weight Polyethylene (UHMW), a premium engineering plastic known for its outstanding wear resistance, chemical stability, and self-lubricating properties. These plastic sprockets are widely used in food processing, packaging, conveyor systems, and various types of automation equipment.

Compared to traditional metal sprockets, UHMW sprocket offers superior durability, quieter operation, and exceptional resistance to corrosion and harsh chemicals, making them the ideal solution for demanding environments.

Applications of UHMW Sprockets

- Food processing and packaging equipment

- Beverage filling and bottling lines

- Pharmaceutical manufacturing systems

- Automated production and conveyor lines

- Agricultural and outdoor machinery

- Chemical and corrosive industrial environments

UHMW Sprockets' Key Features:

- Exceptional Wear Resistance: UHMW material offers excellent abrasion resistance, significantly extending product lifespan compared to standard plastics and even some metals.

- Corrosion & Chemical Resistant: Perfect for moist, corrosive, or chemically aggressive environments—ideal for food and pharmaceutical industries.

- Self-Lubricating & Low Maintenance: No need for additional lubrication. The material’s natural low-friction properties reduce wear and simplify maintenance.

- Noise Reduction: UHMW sprocket minimizes operating noise, creating a quieter and more comfortable working environment.

- Rust-Free: Unlike metal sprockets, UHMW components do not rust or degrade in humid or outdoor conditions.

- Food-Grade Available: We offer FDA-compliant UHMW materials that meet hygiene standards for food and beverage processing.

- Fungal & Bacterial Resistant: Smooth, non-porous surface prevents microbial buildup, ensuring sanitary operation in sensitive environments.

Custom Fabrication:

We offer fully customizable UHMW sprockets based on your specific pitch, tooth count, bore size, and operational requirements. Our technical team is ready to provide tailored solutions to ensure optimal performance and compatibility with your equipment.

FAQ

What is UHMW, and why is it used for sprockets?

UHMW (Ultra-High Molecular Weight Polyethylene) is a highly durable thermoplastic known for its excellent wear resistance, low friction, and chemical stability. It is ideal for sprockets because it provides smooth, quiet operation, requires little to no lubrication, and withstands harsh environments better than metal alternatives.

Can UHMW sprockets replace metal sprockets in all applications?

UHMW sprockets are suitable for many applications, especially where corrosion, moisture, or noise is a concern. However, in high-load or high-temperature environments, metal may still be required. We recommend consulting with our team for proper application matching.

Are your UHMW sprocket food safe?

Yes. We offer UHMW sprocket made from FDA-compliant materials. These are suitable for direct food contact and meet stringent hygiene requirements.

What are the temperature limits for UHMW sprockets?

UHMW performs well in temperatures ranging from -200°C to +80°C (-328°F to +176°F). It is not recommended for high-heat environments beyond this range.

Can you customize sprockets to fit my machine?

Absolutely. We specialize in custom-made UHMW sprockets tailored to your specific pitch, bore size, number of teeth, and application requirements.

How does UHMW handle exposure to chemicals and cleaning agents?

UHMW is highly resistant to most acids, alkalis, and cleaning chemicals, making it ideal for use in environments that require frequent washdowns or chemical exposure.