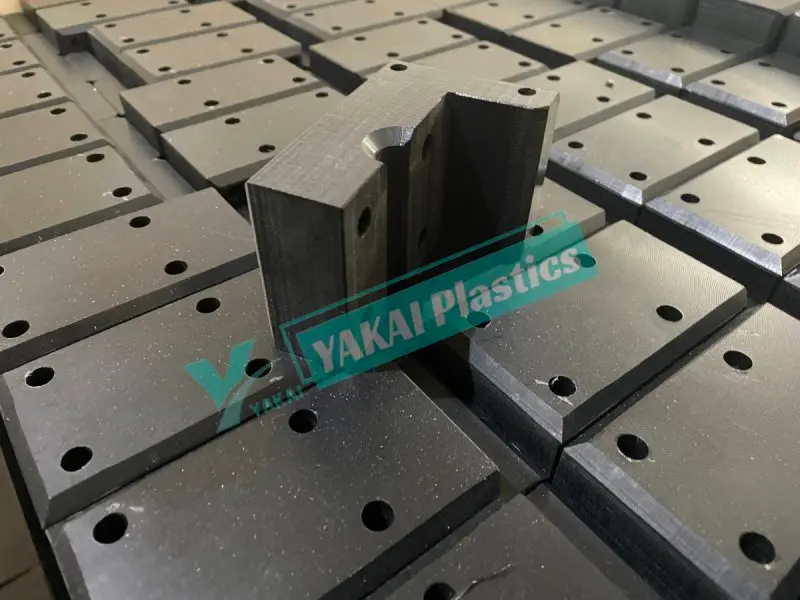

Ultra-high molecular weight polyethylene (UHMWPE) sliders are high-performance engineering plastic materials, characterized by outstanding wear resistance, impact resistance, self-lubrication, and chemical corrosion resistance. These characteristics have led to their widespread application across numerous industrial sectors including mining machinery, coal, cement, steel, power generation, food, textiles, papermaking, chemicals, pharmaceuticals, and electronics.

The primary component of UHMWPE sliders is polyethylene, with molecular weights reaching several million or even tens of millions, endowing them with exceptionally high mechanical strength and wear resistance. Compared to traditional metal materials, UHMWPE sliders exhibit superior impact resistance, enabling them to operate stably in high-speed and heavy-load environments for prolonged periods, significantly extending equipment lifespan.

Furthermore, UHMWPE sliders possess self-lubricating properties, allowing them to operate without lubricants, thereby reducing equipment maintenance costs. Additionally, they demonstrate excellent chemical corrosion resistance, capable of withstanding erosion from various strong acids, alkalis, and organic solvents, ensuring equipment remains operational even in harsh environments.

In the field of mining machinery, UHMWPE sliders are extensively used in equipment such as conveyors, vibrating screens, feeders, and chutes. In these applications, UHMWPE sliders effectively reduce material wear and impact on equipment, enhancing equipment lifespan and stability. Moreover, they can also reduce equipment noise and vibration, improving working conditions.

In industries such as cement, steel, and power generation, UHMWPE sliders find wide application in wear-resistant components of various equipment. For instance, in ball mills in cement production lines, UHMWPE sliders can be used as grinding balls, offering higher wear resistance and longer lifespan. In continuous casting machines in the steel industry, UHMWPE sliders can be utilized as sliding guide rails, improving equipment stability and production efficiency.

Beyond the industrial sector, UHMWPE sliders are also widely used in industries including food, textiles, papermaking, chemicals, pharmaceuticals, and electronics. In these industries, UHMWPE sliders are employed in the manufacture of various wear-resistant and corrosion-resistant components such as gears, bearings, and sliders. Their excellent wear and corrosion resistance enable long-term stable operation in these industries, ensuring normal equipment operation and production efficiency.

In conclusion, UHMWPE sliders are excellent engineering plastic materials with broad application prospects. With the continuous advancement of technology and industrial development, UHMWPE sliders will find application in more fields, making greater contributions to industrial development. Moreover, with increasing focus on environmental protection and sustainable development, UHMWPE sliders, as environmentally friendly materials, will be promoted and applied in more areas.

YaKai Plastics

YaKai Plastics

HelloPlease log in